Going beyond food safety: What Australian food producers need to have in place to initiate and maintain wholesale distribution relationships with large retailers

Just meeting the approximately 2000 pages of the Food Standards Code covers your food business for the very basics. This base level is meant for small, unskilled businesses such as corner stores, sausage sizzles and restaurants to ensure the food we eat is safe.

Where this base level becomes an issue for a food business is when:

1. They want to know their food is edible and nutritious, not just safe

2. They wish to supply a major customer

3. They wish to export

4. They wish to get product liability insurance

The Food Standards Code only requires food to be safe. It does not cover:

1.Food quality: colour, flavour, aroma, texture, etc.

2.Nutrition: There are no rules on minimum or maximum levels of nutrients in most foods unless you make a claim.

3.Weight: Underweight product is not caught by the Food Standards Code, as this is not a food safety issue.

There are over 100 organisations operating in Australia that have introduced standards in excess of the Food Code, some of these well in excess, to ensure food and food ingredients supplied to them meet their own internal requirements. In addition, many overseas countries have strict rules on the standards to which a food business must be certified in Australia, typically well above the Food Code’s requirements. Most insurance companies will not issue product liability or recall insurance to companies that are only certified by local councils to the Food Standards Code, as this base standard only covers the basics of food safety.

If basic food safety is a given, what else needs to be in place to satisfy major retailers?

Most food safety systems for major retail chains are more business management and Quality Assurance systems than food safety programs.

The focus of these standards is not just on quality assurance or processing areas, but a whole of business standard, covering senior management.

A food safety program must be in place covering all steps of the process and all products supplied, from procurement through processing to delivery.

The food safety program must also cover food quality and regulatory issues (for example, correct species, the correct number in cartons, underweights).

It must also meet the international HACCP standards in its formatting and design.

The answer to meeting the basic food standards as well as the requirements from major retail and distribution chains is Enterprise Resource Planning software. And Sage Enterprise Management has the secret formula!

Brett Mundell from Leverage Technologies talks us through choosing an ERP software solution for the food and beverage industry.

Choosing an ERP software solution for the food and beverage industry

Thanks to the team for going through HACCP and traceability requirements. This leads to the next segment today – choosing the right ERP solution for your food processing or food distribution business.

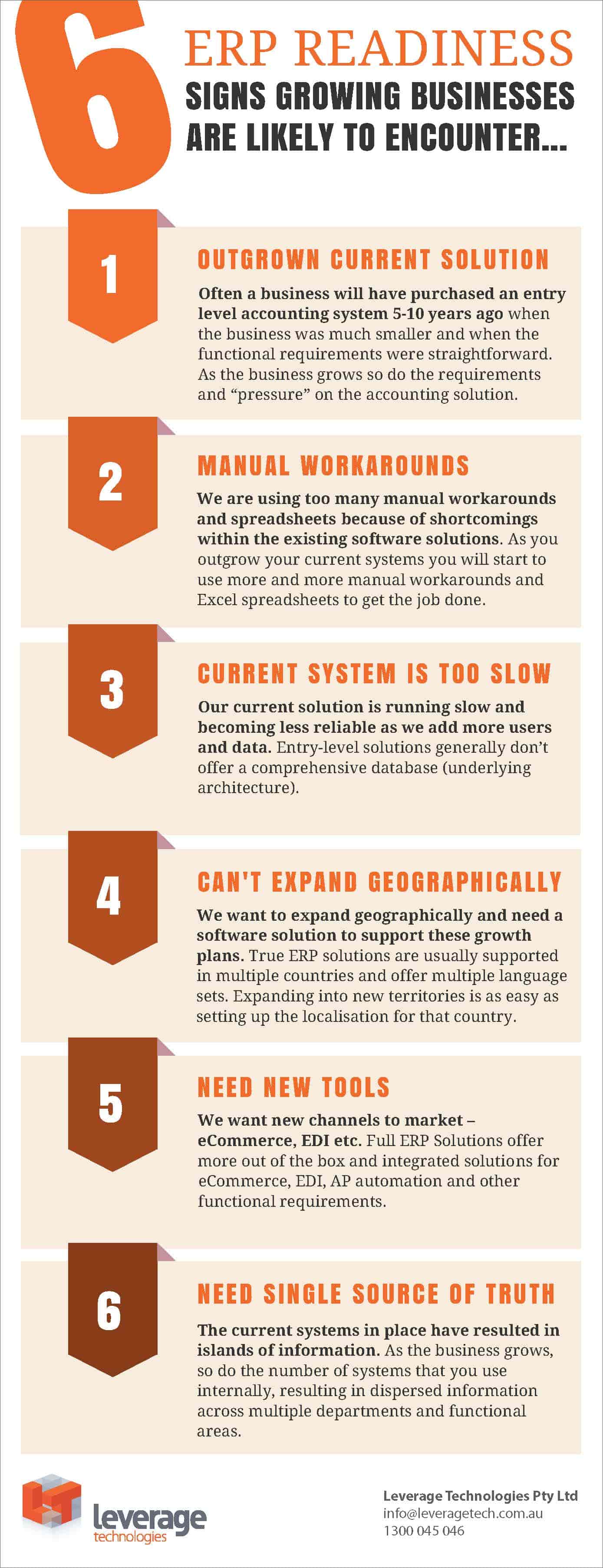

A lot of what we have discussed this morning relates to compliance. Compliance relies on process, structure and systems. Compliance is only one of many reasons to consider an ERP solution. At the end of the day, a well implemented ERP solution will provide assistance with compliance but there are a number of other business reasons for implementing a new ERP solution:

- Improved cash flow;

- Better customer service;

- On time in full delivery.

Always make sure that the systems you are implementing are delivering real business benefits.

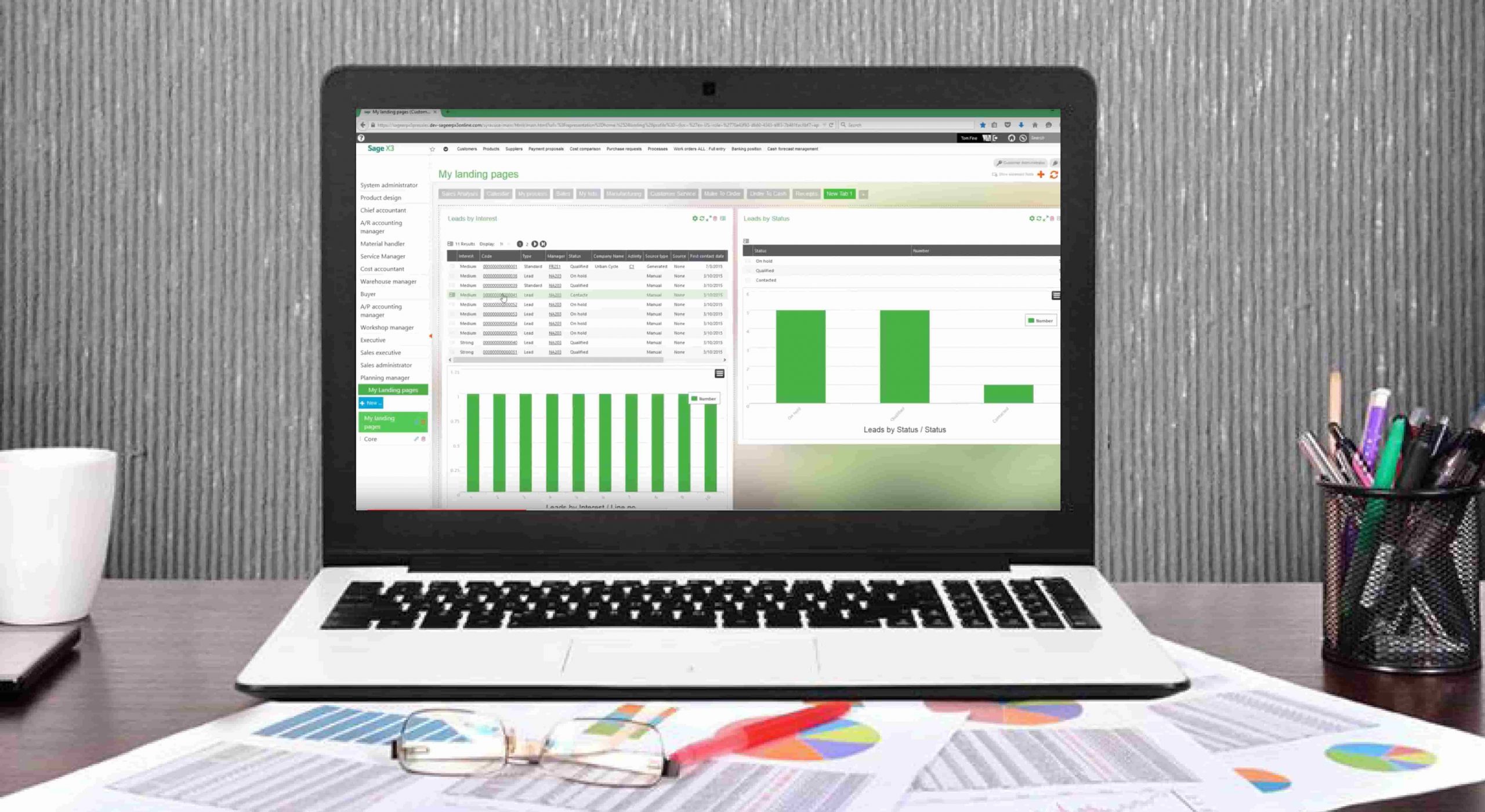

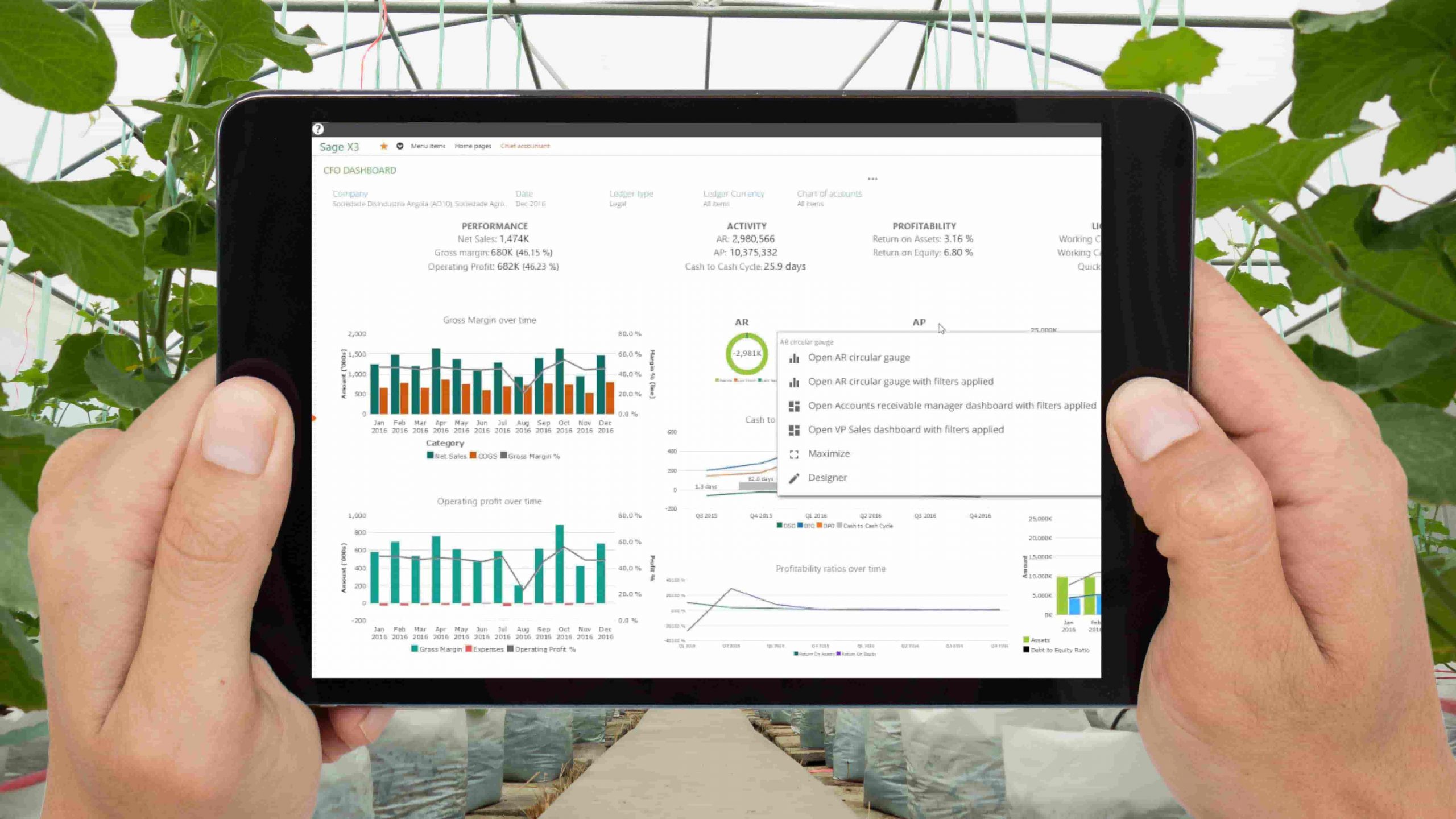

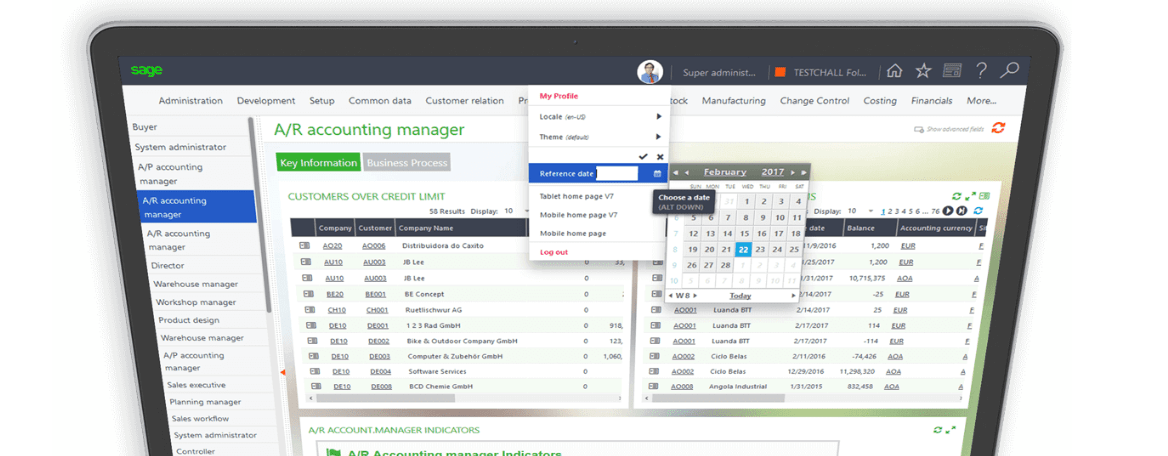

A quick definition – ERP stands for Enterprise Resource Planning and refers to a software solution that consolidates all aspects of your business in a single solution: Finance, Logistics, Customer Relationship Management (CRM), Manufacturing, Service, Reporting. Also included is core functionality for the food and beverage industry – traceability, HACCP, weighing scale integration etc. the assumption is that your ERP solution works across the entire organization to provide you with a single source of the truth and a consolidated view of all operations.

When it comes to ERP solutions for the food and beverage industry – not all systems are created equal. Your choice of ERP ((Enterprise Resource Planning) solution will depend on multiple factors – budget, functional requirements, company size and more. The key, when selecting an ERP solution is to run a comprehensive and structured approach to the selection and implementation process. After all, this is a big investment – in dollar value and time/commitment. Get this project right and your business will reap the rewards – improved cash flow, better information for decision making, improved customer service and better staff retention. But, get the choice of software or implementation wrong and it is a long, hard road to travel. ERP solutions operate across your business and as a result, will have a huge impact on all operations.

We have all heard the horror stories of implementations that have run well over budget and taken years to implement.

The challenge is to run a process of evaluation and selection that leads you through the logical steps of evaluation. Always follow a structured process. This should include:

- Your “how and why” are we planning to do this? Map out your reasons for evaluating a new ERP solution, decide on a budget, put together a high level requirements list (functional and technical), put forward your desired outcomes for success.

- Talk – Discuss your requirements with similar businesses to find out what has and has not worked for them.

- Get online – Go online and do your research. Review multiple systems, on-line demos, system reviews and case studies. This will allow you to narrow down the available choices to five or six potential solutions.

- Ask vendors to respond in writing to your requirements list – Once you have narrowed down your “on-line shortlist” send potential vendors a list of your functional and technical requirements and ask them to respond to your questionnaire in writing. Your questionnaire should be brief (15-20 key questions per functional area). As an example you might be asking: has the vendor had previous experience in the food and beverage industry? Has the vendor helped other food and beverage companies with HACCP compliance? Break the questionnaire into functional areas – general overview, finance, logistics, inventory, manufacturing, reporting. Focus this brief questionnaire on your industry and company-specific requirements – HACCP, weighing scale integration, catch weights, expiry dates etc. Remember to ensure that potential vendors will be able to meet your budgetary expectations. There is no point spending time considering solutions that you cannot afford – budget is a key requirement. Place emphasis not only on the software but also the provider – who will supply the implementation and support services? Has the vendor previous experience in the food and beverage industry? What references can they provide?

- Arrange a shortlist – From the online investigations and the questions that you have sent to suppliers you should be able to reduce your shortlist to three potential suppliers.

- Get demonstrations – Ask vendors to demonstrate their solution for you. These demonstrations should be detailed. Provide your evaluation team with checklists so that they can score the potential providers. The checklist should include important functional areas that you want the demonstration to cover. Remember to let the potential vendors know that they must prepare the demonstration using your data – with specific configuration for food and beverage.

- Propose a shortlist – Shortlist one supplier and then go into overdrive with the evaluation process.

- Get a scope of works completed by the potential provider – This scope of works is not a full system blueprint or functional design – it’s a 20-30 page document that usually takes 2-4 days to put together to make sure that you and your potential ERP provider have covered off on the high-level functional requirements. After this stage of the evaluation process is complete your ERP provider should be able to give you an accurate assessment of project scope (high level), timelines, resource requirements and risks. This document should form the basis of your final proposal.

- Check references – Ask for references in the food and beverage industry. Call these references and have a 15-minute discussion. Have a number of questions ready to ask. How long the solution took to implement? Was the solution delivered on time? What benefits has the company gained from the new solution? Ask about food and beverage-specific requirements and benefits. For example, you might ask about automated EDI for the major Australian retailers and what impact this has had on their business. Learn from this reference call – gain insight into other companies experiences so that you can streamline your implementation process.

- Meet the team – ERP implementations follow a structured methodology. This methodology reduces risk during the implementation and helps ensure an on time, on budget delivery. Even with the best implementation methodology available a critical component for success is the team that you will be working with (specifically the ERP reseller implementation team). Ask to meet (interview) the team. Check the team CV’s – how much business experience (accounting, operations, manufacturing) does the team have, how long have team members worked for the reseller, what specific food and beverage experience do the team members have, how long have the team members been working on the ERP product? You are looking to make sure that the implementation team has the relevant experience (business and ERP) and is a good cultural fit with your team and your business.

- Review agreements – Check the agreements for fairness. Include the scope of works in the agreement. Reference the budget and scope.

- Post-implementation cost of ownership and support – Don’t forget that no evaluation of ERP is complete without evaluating post go-live costs and structures. Include an evaluation of the support desk procedures, what’s included (and not included) in software support.

Specific evaluation criteria for the food and beverage industry include

- HACCP

- Traceability

- Batch control

- Weighing scale integration

- The list goes on!

Each part of your evaluation process should include a review of food and beverage-specific ERP requirements.

There is a balancing act here. You will most likely be looking for a global ERP provider. The reason I say this is that the global vendors offer a more complete solution and less risk. The global ERP vendors have you covered if you want to expand overseas, they offer the latest technological advancements (because they have the money to constantly invest in research and development). Think of technologies like mobility (access your data anywhere, anytime), cloud, AP automation and more.

Most global ERP providers are “generalists” they do not specialize in one industry. Their products are designed to work across multiple industries. So, what you are looking for is a global ERP vendor that has built a vertical market focus in food and beverage. These vendors and resellers will have a proven track record in the food and beverage industry. A lot of the required functionality for food and beverage (traceability, HACCP, expiry dates by customer, where used reports), will have already been built by the ERP reseller. You are getting the best of both worlds – a global ERP solution with all the latest technology with a deep vertical market function set built for the food and beverage industry.

What does the future hold? Technology is moving at a more rapid pace than ever before. As always, we are not interested in technology for the sake of technology. We want real business benefits from our ERP solution. What we can say is this, more than ever before if you do not embrace technology and the digital transformation you will lose ground to your competition who are embracing technology. Let’s open this discussion a little more:

Data – We receive lots of data from multiple different sources: retail data, EDI data, social media, supplier reporting, CRM and more. Data is meaningless unless we have the tools to sort and analyse data. Get organized with Business Intelligence (BI) tools to give you timely, accurate data for better decision making.

Internet of Things (IoT) – connected devices. As the world becomes more connected we are receiving information from multiple connected devices. This will have an impact on how we manage suppliers, customers and team members. In a connected world, the supply chain is managed with much more accurate and up to date information than ever before.

Artificial Intelligence – Information at your fingertips. As an example, early warning systems to assist with pick and pack accuracy, real-time delivery timeframe updates and customer order recommendations. Real, everyday advantages, will be had from AI.

Digital transformation – It’s already happening – all aspects of a business are being affected including Marketing, Operations, Customers, Finance, you name it!

EDI – Powerful order automation.

AP automation – Automate purchase order planning, purchase order generation, workflow and the associated admin to get the job done right every time, on time.

Expense management automation – Automate expense management to streamline your business.

In summary – a structured approach to ERP selection will ensure that you choose the right ERP solution for your business.

For more information or to learn how Sage Enterprise Management can streamline your Food & Beverage manufacturing business call us on 1300 045 046 or email [email protected].